Non-isolated battery management solution specifically for auxiliary battery packs AEK-POW-BMSNOTX

Product introduction

AEK-POW-BMSNOTX is a battery management system (BMS) evaluation board that can manage 4 to 14 battery cells. The board is based on the L9963E lithium-ion battery monitoring and protection chip and is suitable for high-reliability automotive applications. The main function of the L9963E is to monitor the status of the battery and battery nodes through stack voltage measurement, cell voltage measurement, temperature measurement and coulomb counting. Measurement and diagnostic tasks can be performed on demand or periodically at programmable cycle intervals. The measurement data is available to an external microcontroller to perform charge balancing and calculate state of charge (SOC) and state of health (SOH). The embedded L9963E can act as a transceiver, communicating directly with the MCU via SPI.

This board is particularly suitable for auxiliary battery systems that supply power to devices connected to the vehicle (such as audio systems, window cleaning systems, seat heating, lighting systems, light signals, climate control systems) even when the engine is not running, ensuring the main start The battery is reserved for engine starting and vehicle electrical requirements.

AEK-POW-BMSNOTX provides an elaborate monitoring network to sense the voltage of each cell. Can sense the current of the entire battery pack. This sensing can detail the SOC of each battery cell and thus the state of charge of all battery packs. The SOC allows an assessment of the remaining battery capacity, which is equivalent to the remaining driving range. For maintenance reasons, it is important to monitor SOC estimates over time. According to our SOC calculation algorithm, the greater the difference between the SOC and its nominal value (i.e., the value when the battery was new), the greater the risk of over-discharging the battery pack cells. The evolution of SOC over time therefore allows the assertion of the state of health (SOH) of a cell or battery pack to detect early signs that the battery is at risk of over-discharging or over-charging.

The SOC of a battery cell is required to maintain its safe operation and duration during charging, discharging, and storage. However, SOC cannot be measured directly but is estimated based on other measurements and known parameters such as characteristic curves or look-up tables. This information on the battery cell is necessary to determine how voltage changes with current, temperature, etc., based on the battery chemistry and the production batch used. Access to various battery data models thanks to a partnership with About:Energy.

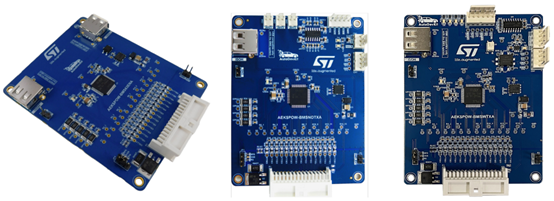

In the AutoDevKit ecosystem package, we created a sample to detail SOC and SOH using Li-ion batteries. Battery packs may have different SOCs and must be balanced to get them all to the same charge level. After detecting the lowest charge in the battery pack, all other battery nodes are discharged to reach its level. This demonstration explains how to activate the L9963E's internal MOSFET, which shorts the battery across an external dissipation resistor (the resistor is already mounted on the board) to discharge it. Passive cell balancing can be done via L9963E internal MOSFETs or external MOSFETs. The controller can manually control the balancing driver or initiate a balancing task with a fixed duration. In the second case, the balance can be programmed to continue. Even when the IC enters a low-power mode called Silent Balance, it avoids drawing unnecessary current from the battery pack. The balancing function is necessary to extend the battery capacity and its duration. Different MCUs can be used. In our demonstration we used the AEK-MCU-C4MLIT1 as well as other ASIL-B and ASIL-D microcontrollers from the SPC58 Chorus family.

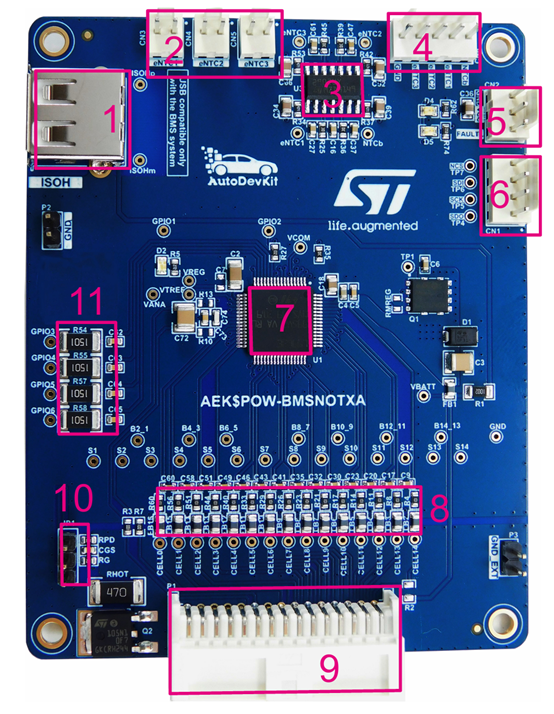

Product block diagram overview

1.ISOH port for connecting the board to the AEK-POW-BMS63EN in a daisy chain.

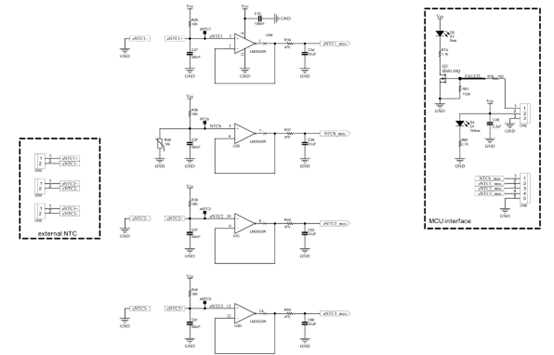

2.CN3, CN4, and CN5 connectors for connecting three external NTC sensors.

3.LM2902W low-power quad-channel operational amplifier.

4.CN6 connector for MCU ADC, dedicated for NTC sensor readings.

5.CN2 connector for diagnostic functions.

6.CN1 connector for communicating with the MCU board via SPI.

7.L9963E AEC-Q100 qualified automotive multi-cell battery monitoring and balancing IC.

8.Balancing resistor.

9.Battery pack connector.

10.Hot swap protection.

11.GPIO for external NTC connection, handled by L9963E.

Main features of the product

This board contains the AEC-Q100 qualified L9963E automotive multi-cell battery monitoring and balancing IC

Voltage monitoring of each battery cell and entire battery node

Current sensing across battery nodes

4 GPIOs for connecting NTC sensors on the battery pack connector

3 NTC sensors, connectable to CN3, CN4 and CN5 connectors

1 NTC sensor for measuring board temperature

CN1 connector for communicating with the MCU board via SPI

CN2 connector for diagnostic functions

CN6 connector for MCU ADC, dedicated for NTC sensor readings

Provides passive balance

Compact size: 100 mm x 76 mm

Included in the AutoDevKit ecosystem

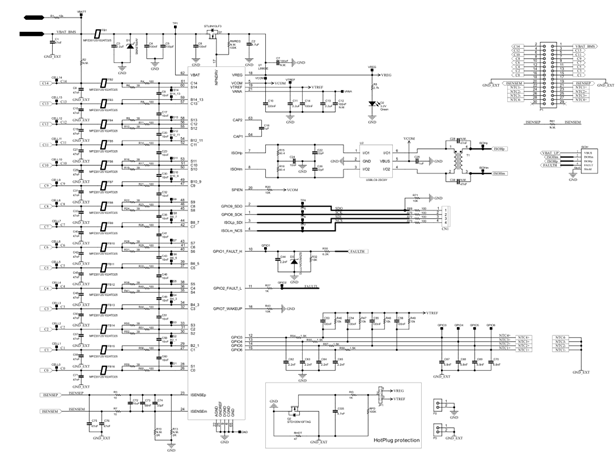

Product schematic diagram