ST Stellar-E SR5E1 22KW OBC combo 3KW DC-DC car charger solution

With the global awareness of environmental protection rising, the global automobile industry is slowly entering the era of electrification to reduce carbon emissions. The vehicle system is mainly composed of battery, electric drive and electronic control. The battery system is the power source of the vehicle, and the OBC system for charging the battery is even more important. A highly secure and efficient OBC system is bound to be needed by the entire industry.

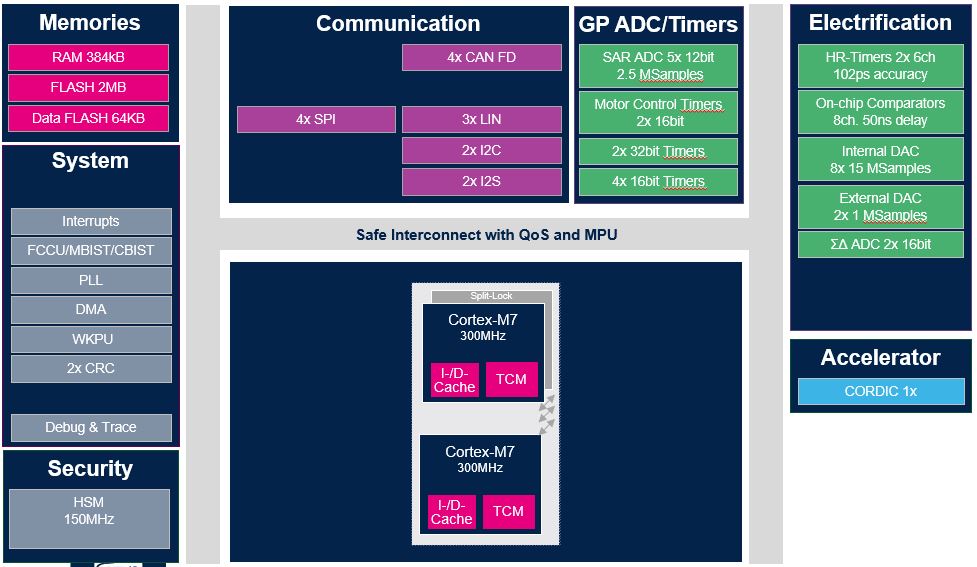

Stellar-E - an automotive-grade processor with high security

1. Stellar-E (SR5E1)

In the era of information explosion, the protection of automobile information is becoming more and more important. The Stellar series of chips developed by ST specifically for automobiles have a high degree of information protection function.

Requirements for electric vehicles include robust hardware to ensure efficient power conversion and performance with superior safety and security. The ability to receive regular over-the-air software updates is at the heart of the feature enhancements and ensures critical safety and security updates are delivered throughout the vehicle lifecycle. Improved user experience with enhanced range and performance and the latest security updates. The key to the superior performance of electric vehicles lies in the car’s components and how they combine advanced digitalization with efficiency and innovation. The OBC system designed using the Stellar-E series can bring 22KW of energy to charge the car battery, and it is also combined with 3KW of DC power for use in the car.

In this article, we will conduct an in-depth discussion from the chip advantages of Stellar-E to the design of the OBC system and its future prospects.

ST original Stellar-E introduction website: https://www.st.com/en/automotive-microcontrollers/stellar-actuation-mcus.html

2. Features of Stellar-E

•AEC-Q100 automotive certification

•SR5 high-performance analog mcu: digital and analog high-frequency control technology (SiC and GaN) for new wide-bandgap requirements

•Excellent real-time and functional safety performance (ASIL-D)

•Built-in fast and cost-optimized OTA (over-the-air) reprogramming capabilities

•High Speed Secure CryptoService (HSM)

•Dual-core 2x 32-bit Arm® Cortex®‑M7 300MHz computing power 3. Stellar-E SR5E1 processor block diagram

22KW OBC System Combo 3KW DCDC

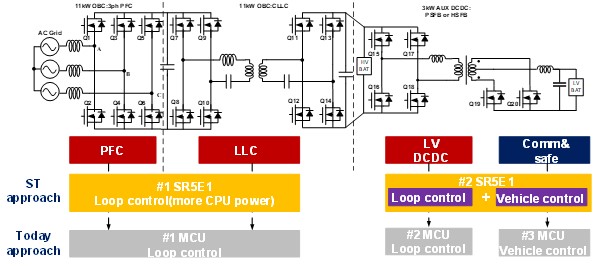

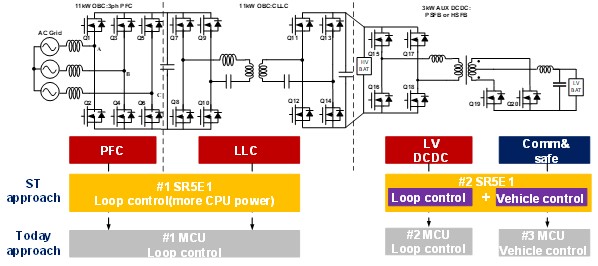

The design of the 22KW OBC system is mainly designed with three power supply topologies. The circuit block diagram is shown below.

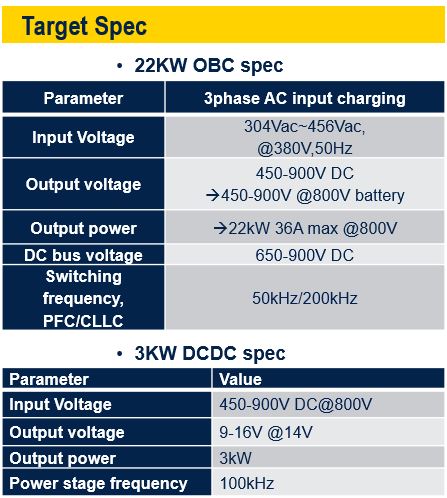

1. 22KW OBC combo 3KW DC-DC specifications

2. 22KW OBC combo 3KW DC-DC Features

• Faster control loop optimal utilization for SiC/GaN

•High resolution timer (HRTIM) for SiC/GaN

•Supports 3KWDC-DC peak current mode control (PCMC)

•Supports two control combinations of CLLC: (1).PFM+phase shift control (2).Peak current mode control (PCMC)

•CRM controlled PFC

•Has bi-directional power supply function, can be charged and discharged

• Fully supports power output of 3.3KW, 6.6KW, 11KW and 22KW

•Single-phase/three-phase PFC switching

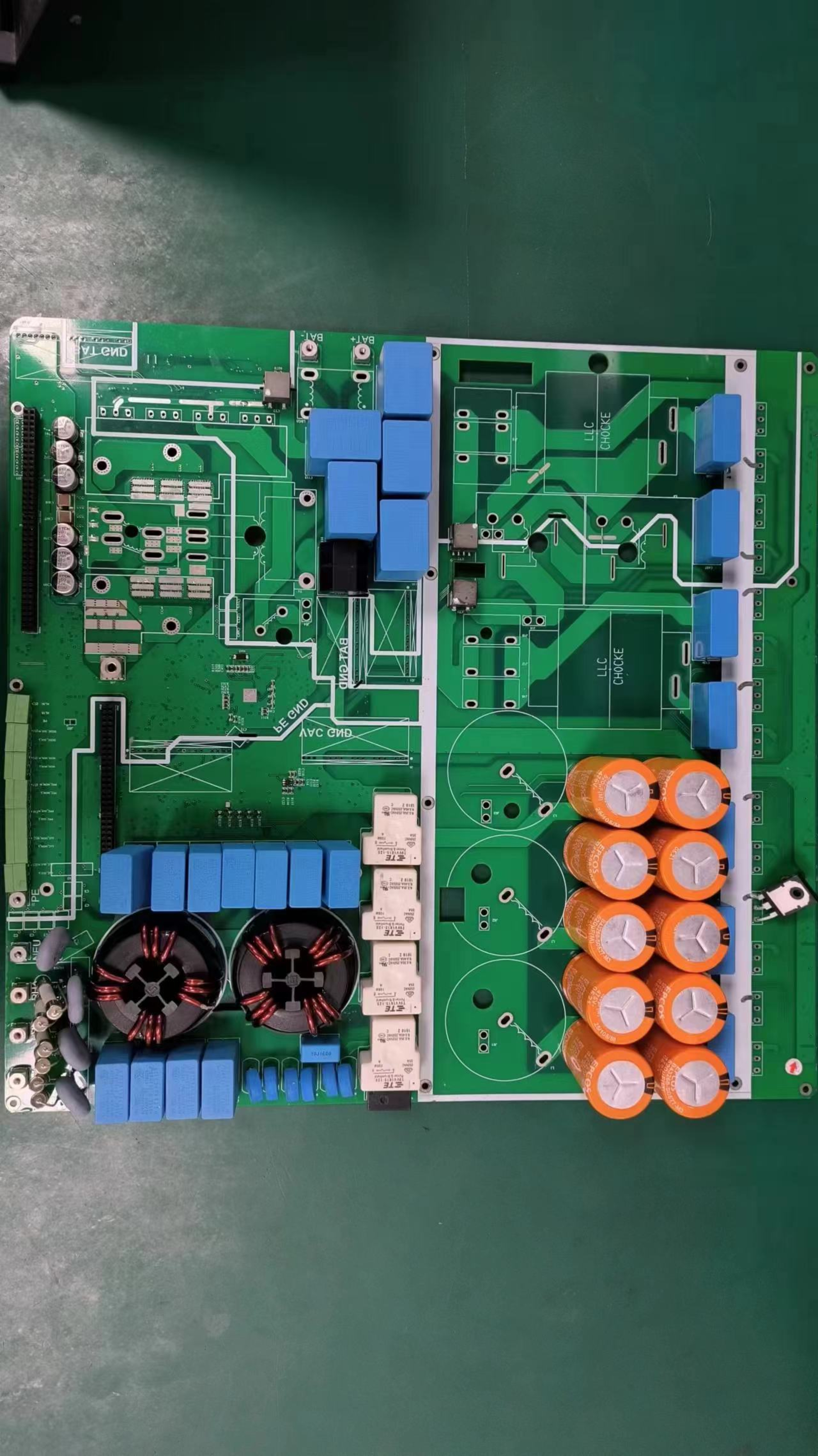

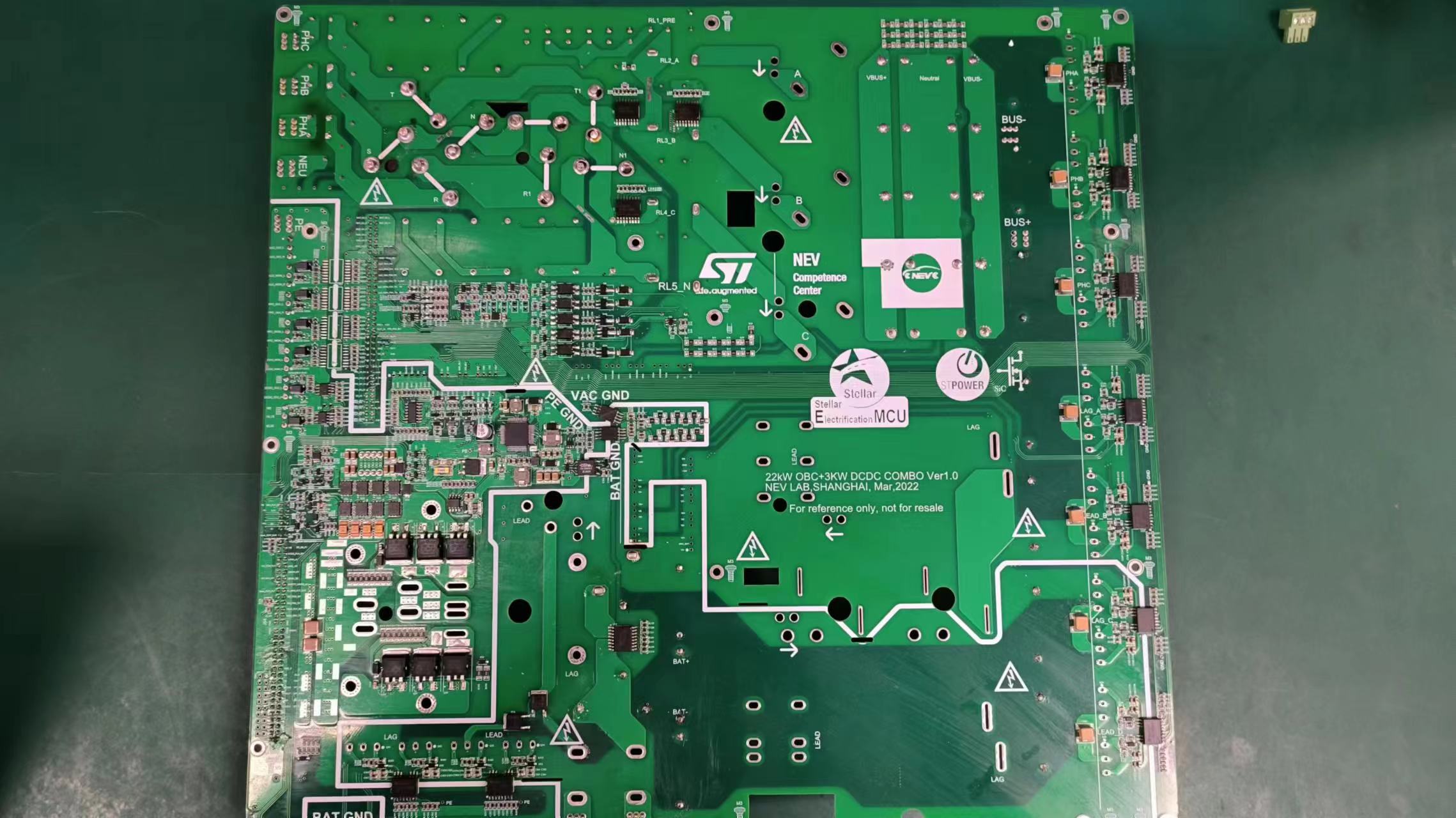

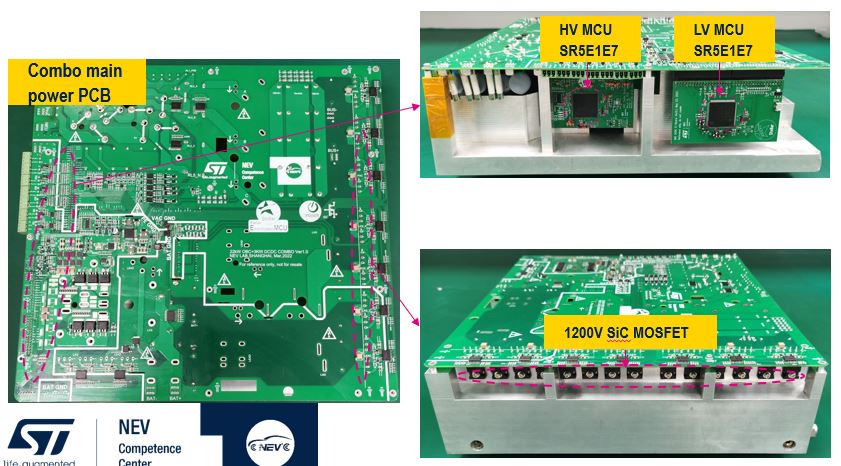

3. 22KW OBC combo 3KW DC-DC development board

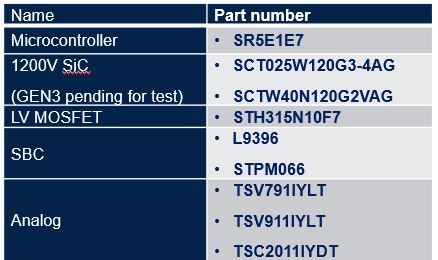

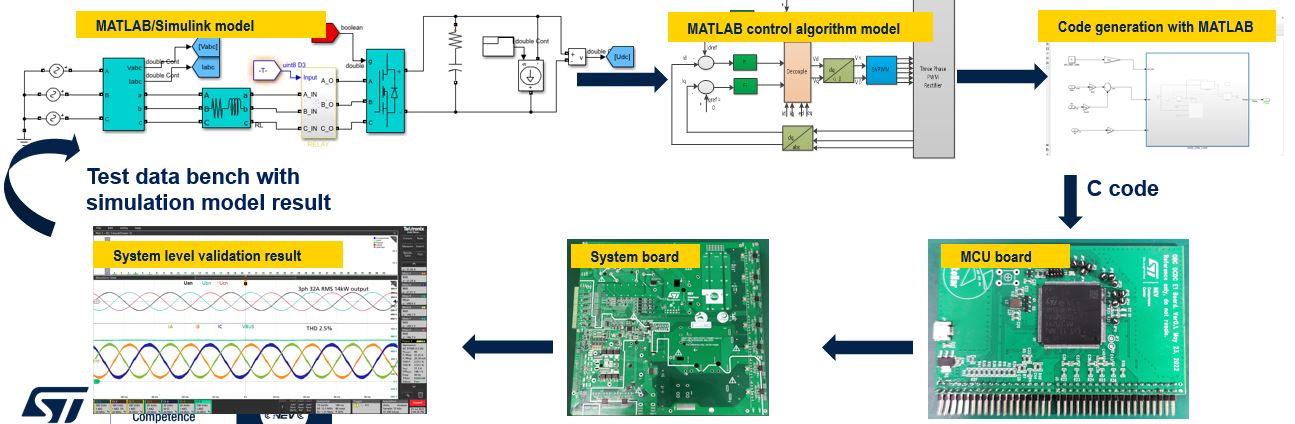

4. 22KW OBC combo 3KW DC-DC Main materials 3. Rapid control prototype development

•Speed up the development process and shorten development time

•Using MBD method, running 3ph PFC (800V) with the first STAR-E microcontroller sample within 2 months

•Prototype development, reference designs, solution development

•Provide a complete support package to shorten the customer system evaluation cycle

Future outlook

At the heart of any electric (EV) or plug-in hybrid (HEV) vehicle design lies the high-voltage (200 to 800 VDC) battery and its associated charging system. Using an on-board charger (OBC), you can charge your battery from AC power at home or at an outlet at a private or public charging station. From 3.6 kW single-phase to 22 kW three-phase high-power converters, with the use of third-generation semiconductors SiC and GaN, OBCs must now have the highest efficiency and reliability to ensure fast charging and meet limited space and weight requirements . In terms of future high-security power supply design, the Stellar-E series can meet the charging design needs of its electric vehicles.

Scenario application diagram

Display board photo

Solution block diagram

Core technical advantages

Requirements for electric vehicles include robust hardware to ensure efficient power conversion and performance with superior safety and security.

The ability to receive regular over-the-air software updates is at the heart of the feature enhancements and ensures critical safety and security updates are delivered throughout the vehicle lifecycle.

Improved user experience with enhanced range and performance and the latest security updates.

The key to the superior performance of electric vehicles lies in the car’s components and how they combine advanced digitalization with efficiency and innovation.

Solution specifications

1. CRM controls single-phase/three-phase bridgeless totem pole PFC

Input: 304Vac-456Vac

Output: 450Vdc-900Vdc

2. 22KW OBC

Input: 450Vdc-900Vdc

Output: 36A Idc MAX.

3. 3KW DC-DC

Input: 800Vdc /3.75A Idc

Output: 14Vdc / 215A Idc