Why PCB controls 50 ohm impedance

single-ended network in the design is generally controlled by 50 ohms, so many people will ask, why is it required to be controlled by 50 ohms instead of 25 ohms or 80 ohms? First of all, 50 ohms is selected by default, and everyone in the industry accepts this value. Generally speaking, it must be a standard set by a recognized organization, and everyone designs according to the standard.

Using the reference clock to realize serial communication data recovery of Cyclone10LP devices

In the non-source synchronous low-speed serial data communication scenario, the clock frequency of the communication counterpart may be biased, which may cause the data receiving end to be unable to accurately sample. In this case, the SOFT-CDR and DPA functions in the high-speed transceiver or LVDS serdes of high-end Altera devices can effectively solve this problem.

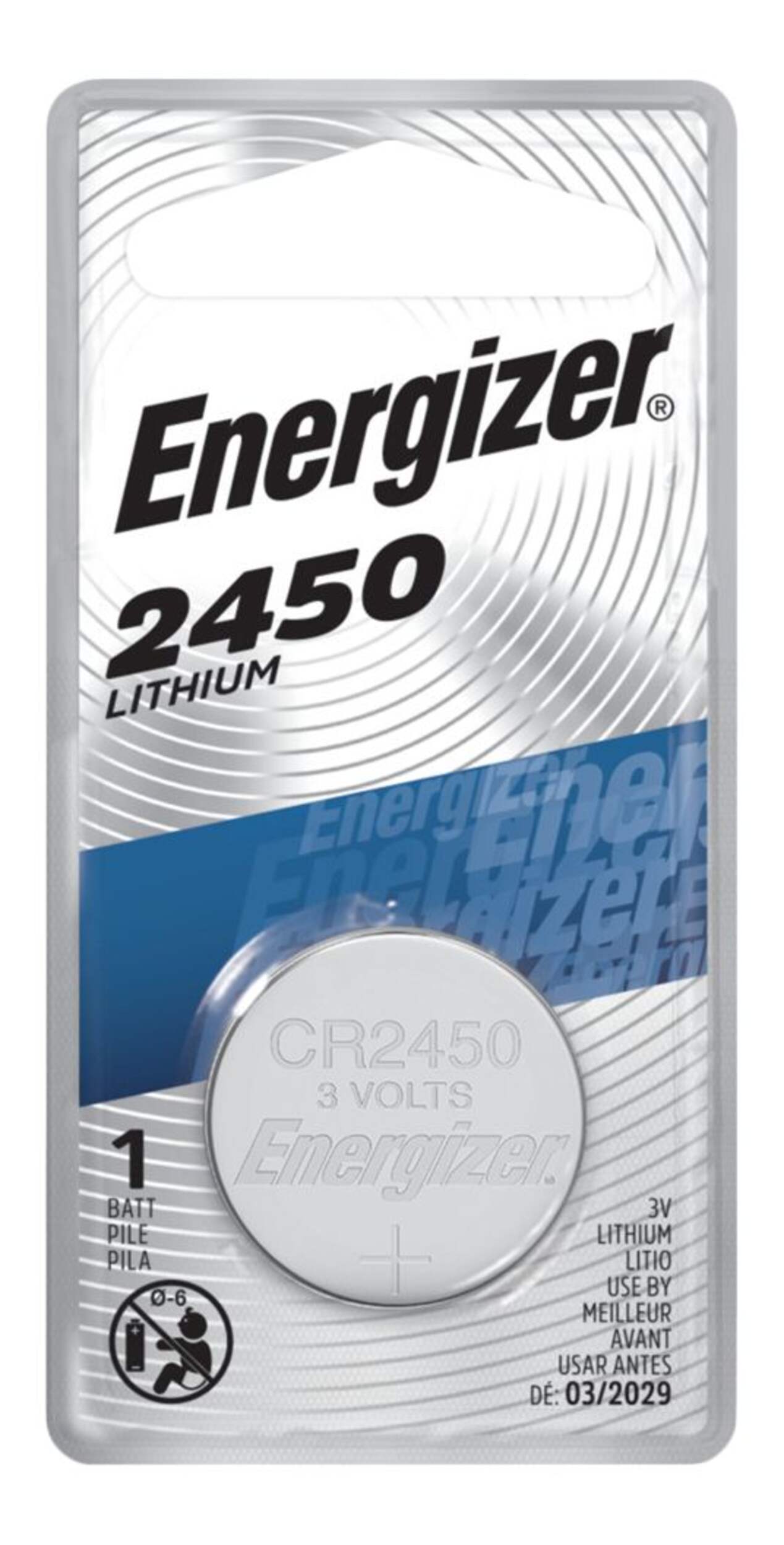

CR2032 vs CR2450 batteries: Which one is better for your device?

Many daily devices use CR2032 and CR2450 batteries because of their small size and reliable performance.

7408 Integrated Circuit: A Classic TTL (transistor-transistor logic) Type IC

The 7408 integrated circuit is a classic TTL (transistor-transistor logic) type IC, which is widely used in various digital circuits. It contains four 2-input AND gates, each with two inputs and one output, for performing logical AND operations.

What is Transistor hFE

hFE, also known as current gain or β (Beta), is an important parameter of the transistor, which represents the ratio between the base current and the collector current. It describes the gain capability of a transistor when amplifying current.

IGBT vs. MOSFET: A Comprehensive Comparison of Features

Both IGBTs and MOSFETs are important semiconductor devices that are widely used in power electronics, switching power supplies, and other high-power control systems. They can both be used to control the flow of current, but their operating principles, characteristics, and application scenarios differ.

WiFi 7 vs WiFi 6: Wireless Network Routing Comparison

WiFi 7 (802.11be) and WiFi 6 (802.11ax) are both wireless network communications standards, but they have significant differences in performance, spectral efficiency, latency, and the number of devices they support.

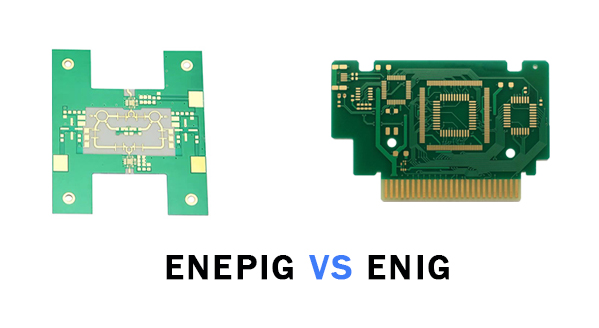

ENIG vs ENEPIG PCB: Explore the Difference

The choice of PCB surface finish is more than just a detail; it determines the performance and lifespan of the PCB. The versatile and robust Electroless Nickel Electroless Palladium Immersion Gold (ENEPIG) and the reliable and classic Electroless Nickel Immersion Gold (ENIG).

The automotive crystal oscillator FA-238A is the preferred choice for car Bluetooth

Epson FA-238A is a high-performance quartz crystal oscillator widely used in automotive, industrial and consumer electronics fields. It is particularly suitable for automotive-grade and high-reliability applications, with excellent temperature stability, low power consumption and high precision.

What are the differences between tantalum capacitors and ordinary capacitors

Tantalum capacitors are often used in high-precision circuits due to their high reliability, stability and small size, but due to their high price and polarity requirements, special attention should be paid to the connection polarity during design.

What is a clamping diode? Principle, function and application analysis

Clamping diodes are a common electronic component, also known as protection diodes or baropendulum diodes.

Four Common Topological Approaches to Powering LEDs

There are many topologies that can be used to power LEDs. As you probably already know, you need to first identify your design requirements before you start selecting, or you may end up with a design that is less than ideal or, worse, not guaranteed to work properly over the long term.

Regionalization Trend of Global Electronic Component Manufacturing: The Impact of Multinational Joint Ventures and Supply Chain Diversification

As global supply chain pressure increases, more and more electronic component companies are establishing production bases in places such as India and Southeast Asia, promoting the regionalization of supply chains.

US CHIPS Act 2024 in-depth implementation: How to reshape the global semiconductor supply chain and the future of technology

In August 2024, as the CHIPS Act is further promoted, the United States strives to localize the semiconductor industry and reduce external dependence. This strategic transformation is reshaping the global chip supply chain and is crucial to the future development of emerging technology fields such as AI and big data. This article deeply analyzes how the CHIPS Act reshapes the global supply chain and brings key industry impacts.

Hisense TVs sold out in Walmart on Black Friday

During this year's Black Friday promotion, Hisense TVs once again became a hot-selling product in the United States. Recently, a large number of videos of Americans rushing to buy Hisense TVs appeared on social media.

ENIG vs ENEPIG PCB: Explore the Difference

ENIG (Electroless Nickel Immersion Gold) and ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) are both common printed circuit board (PCB) surface treatment processes. They are both used to provide good soldering performance, corrosion resistance and reliability, but they differ in certain applications and requirements.

What is ENIG (Electroless Nickel Immersion Gold)

ENIG is a common surface treatment process involving two layers of metal coating:

Nickel layer: formed by chemical nickel plating process, the main purpose is to provide a solid metal layer to ensure good solderability and prevent copper layer oxidation.

Immersion gold layer: A thin layer of gold is covered on the nickel layer, usually with a thickness of about 0.03 microns. This layer of gold can protect the nickel layer from oxidation and improve solderability.

What is ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold)

ENEPIG is an improved version of the surface treatment process involving three layers of metal coating:

Nickel layer: Like ENIG, nickel is plated first.

Palladium layer: A layer of palladium is plated on the nickel layer. This palladium layer can improve weldability, corrosion resistance and oxidation resistance.

Immersion Gold: Finally, a thin gold layer is applied to prevent the palladium layer from oxidizing and improve welding reliability.

ENIG vs ENEPIG: A Comparative Analysis

| Features | ENIG (Electroless Nickel Immersion Gold) | ENEPIG (Electroless Nickel Electroless Palladium Immersion Gold) |

|---|---|---|

| Metal coating layers | Nickel layer + immersion gold layer | Nickel layer + palladium layer + immersion gold layer |

| Oxidation resistance | Weak (vulnerable to moisture and oxidation) | Strong (palladium layer provides additional protection) |

| Welding performance | Excellent, but the gold layer may wear | Better, the palladium layer improves welding reliability |

| Corrosion resistance | Good | Better, the palladium layer increases corrosion resistance |

| Applicable scenarios | Ordinary consumer electronics, computer hardware, automotive electronics, etc. | High-end electronics, automotive electronics, aerospace, medical equipment and other fields with high reliability requirements |

| Cost | Low | High, because palladium is expensive |

| Production process | Simple, suitable for large-scale production | More complex, requires more process steps |

| “Black gold” problem | Yes (if the gold layer is not properly treated) | No, because the palladium layer can prevent the gold layer from reacting with the nickel layer |

1. Layer Configuration

ENEPIG: This finish consists of three layers: a nickel base layer, a palladium layer, and a gold top layer. The palladium acts as a barrier between the nickel and gold layers.

ENIG: ENIG also includes two layers on a copper substrate, but only nickel and gold. ENEPIG does not have a palladium layer.

2. Corrosion resistance, reliability

ENIG: ENIG has excellent corrosion resistance, but is susceptible to black pad syndrome due to direct contact between the nickel and gold layers.

ENEPIG: ENEPIG's palladium layer provides additional protection against corrosion, especially black pad syndrome, a defect that occurs in ENIG finishes. This makes ENEPIG more reliable for long-term use.

3. Wire bonding capability

ENIG: ENIG is generally suitable for soldering, but is not recommended for wire bonding because the gold layer may become brittle.

ENEPIG: ENEPIG is versatile and suitable for both soldering and wire bonding. This makes it ideal for complex, high-reliability applications.

4. Cost considerations

ENIG: ENIG is generally less expensive than ENEPIG and is a cost-effective choice for standard PCB applications.

ENEPIG: The addition of a palladium layer to ENEPIG may make it more expensive than ENIG. However, the increase in reliability can justify the cost in high-reliability applications.

5. Application Suitability

ENIG: Ideal for general PCB applications where only soldering is required. Widely used due to its good solderability and flat surface.

ENEPIG: Ideal for complex, high-density boards where reliability is critical. Compatible with soldering and wire bonding, making it suitable for a wide range of electronic applications.

ENIG VS ENEPIG:Making the Right Choice

ENIG is suitable for most general electronic applications, with low cost and sufficient performance to meet general needs, but may face gold layer wear and "black gold" problems in demanding environments.

ENEPIG provides higher oxidation resistance, welding performance and reliability, and is particularly suitable for applications that require higher quality standards, such as automotive electronics, medical devices, aerospace, etc., but at a higher cost.

Choosing between ENEPIG and ENIG depends largely on the specific requirements of your PCB application. If you need a finish that offers exceptional wire bonding capabilities, corrosion resistance, and durability for high-reliability applications, ENEPIG is the way to go. However, for standard applications where cost is a significant factor, and solderability is the primary concern, ENIG presents a more feasible option.

Remember, the right surface finish not only enhances the performance of your PCB but also extends its lifespan, ensuring reliability and efficiency in your electronic applications.

Which process to choose depends on the specific requirements of the application, including budget, performance requirements and reliability requirements.